introduction

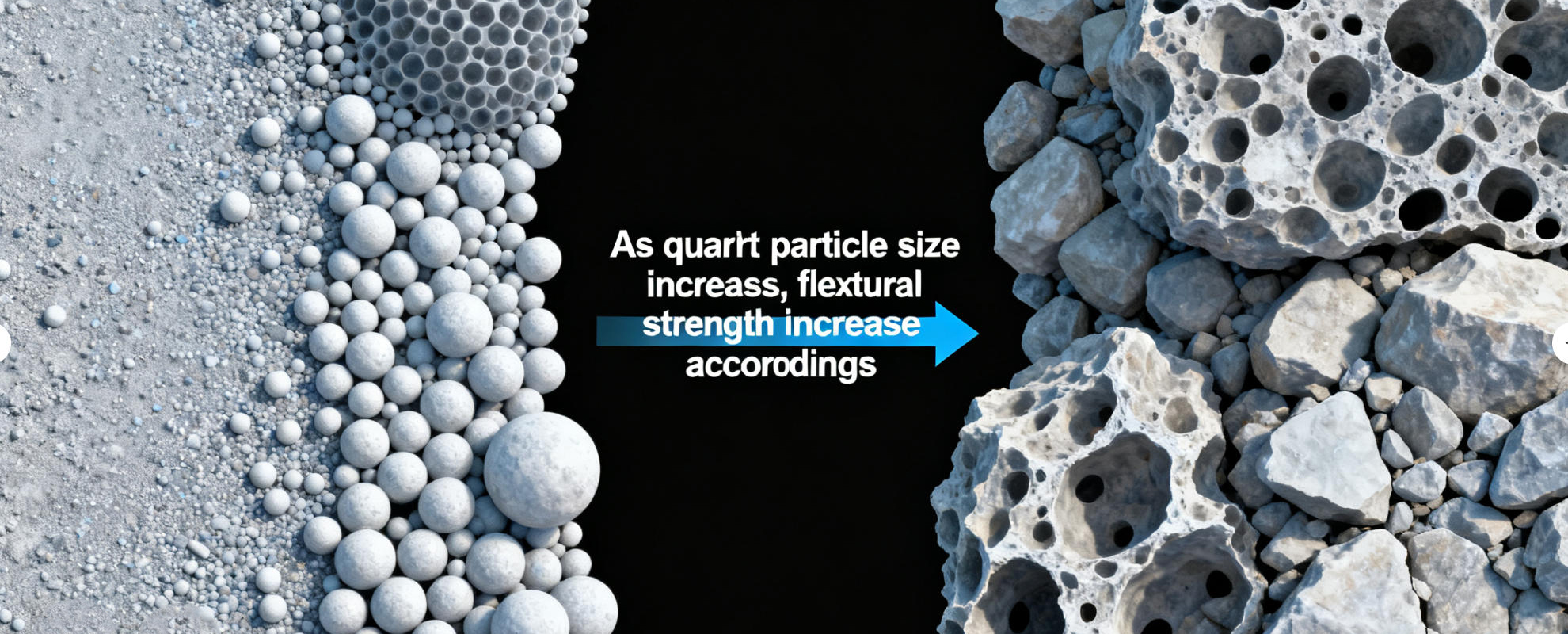

Quartz enhances thermal and dimensional stability, thus preventing warping and deformation. The effect of quartz particle size on bending strength is much greater than that of firing temperature and quartz content. In the range of 10-30 microns, the flexural strength increases as the quartz particles increase in size – because finer quartz particles dissolve faster before the larger particles decrease significantly in size.

This leads to a shift in pore morphology: larger, irregular, interconnected pores formed by coarse quartz particles into smaller, spherical, solitary pores formed by fine quartz particles. However, for vitreous materials such as porcelain, quartz particle size is considered a key factor affecting bending strength.

|

The effect of particle size on strength

Microstructure and porosity:

Fine particles: Form a denser and more uniform microstructure, where small isolated pores are less likely to become crack propagation paths.

Larger particles: Lead to an uneven microstructure, with larger interconnected pores that can transmit cracks and weaken material strength.

Residual Stress:

When ceramics cool, larger quartz particles induce more compressive stress in the surrounding glassy matrix, thereby enhancing the overall strength of the material.

Fine particles can improve densification, but compared to the optimal particle size, they lead to a reduction in residual stress.

Sintering Process:

Smaller particles require lower temperatures to achieve complete dense sintering, thereby reducing firing costs.

It is necessary to balance densification and strength to achieve the optimal particle size;

Defect size:

The maximum defects such as pores or cracks determine the material strength.

Fine particles can form microstructures with smaller and controllable defects, thereby enhancing strength.

Key Points

Using finer quartz particles typically increases the flexural strength of sanitary ware.

The strength enhancement stems from a denser microstructure—fewer and smaller pores.

Using the optimal particle size range can significantly improve mechanical properties.

In summary:

Quartz particle size is a crucial microscopic factor determining the final strength and reliability of sanitary ceramic products. Studies show that optimizing particle size within the range of 10-30 micrometers is far more critical than adjusting firing temperature or quartz content.

By adopting finer and more evenly distributed quartz particles, the formation of a denser and more uniform microstructure in ceramic bodies during sintering can be effectively promoted. This structure significantly reduces the number and size of internal pores and transforms harmful interconnected pores into isolated closed pores, thereby greatly hindering the initiation and propagation paths of cracks. Ultimately, this micro-level optimization directly translates into a significant improvement in the product's macroscopic flexural strength, dimensional stability, and overall quality.

Therefore, in the formulation design and process optimization of sanitary ceramic, controlling the particle size of quartz raw materials as a core component is a scientific and effective approach to achieving high-performance and high-value-added products.